Multistage Turbo Blower

- Home

- Multistage Turbo Blower

Contact Us

Phone Number

+1 832-532-3112 (USA)

Email Address

info@lonestarturbo.com

Office Address

8883 West Monroe Road Houston, Texas 77061, USA

Multistage Turbo Blower

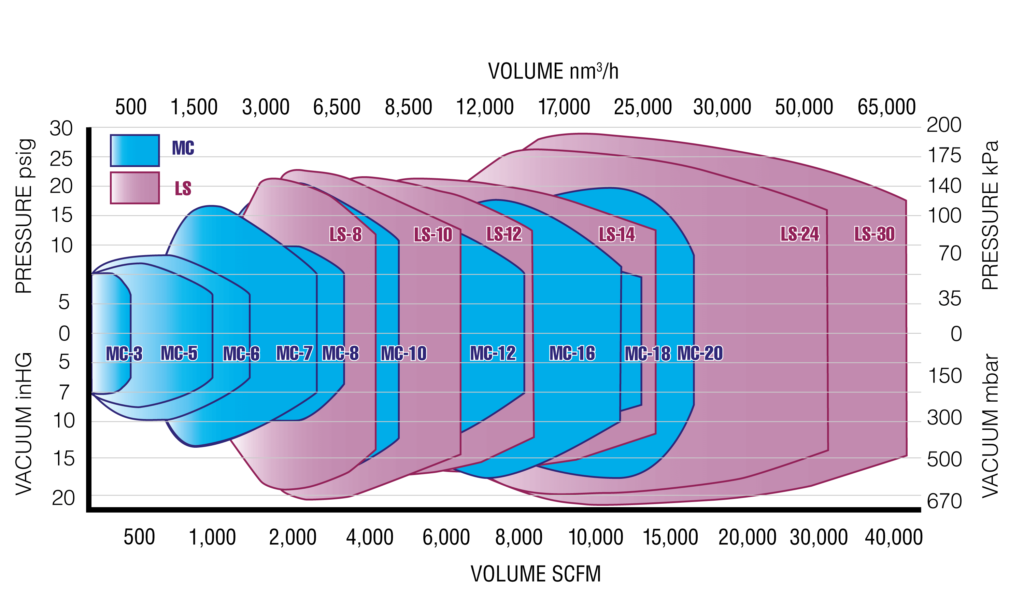

For Air or Gas in Pressure or Vacuum Applications

The MC Series is the most advanced of its kind – the first multistage designed specifically for variable speed operation.

Designed and built by 20-year industry veterans in the USA, the MC series offers superior performance range and efficiencies compared to traditional designs. These blowers are adaptable for air or process gas in pressure or vacuum applications.

- • High Efficiency

- • Designed for Variable Speed Operation

- • Highest Pressure Range (+40% more than anyone)

- • Flow Range from 100% to 40%

- • Large Diameter Impellers (Less stages required to reach pressure)

- • Adapted for Many Applications

- • Made in USA

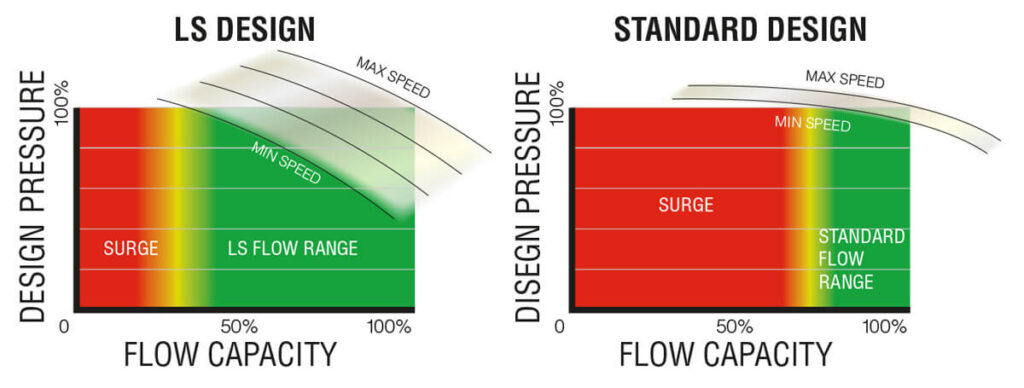

Designed for Variable Speed Applications

The MC Series, Multistage Centrifugal Blower, are the first multistage blowers designed to run with variable speed. A steeper rise to surge provides a wider flow range when adjusting speed over the traditional designs that were based on constant speed operation.

The large diameter impellers produce high tip speed to maintain pressure and backward curved impellers allow a high rise to surge.

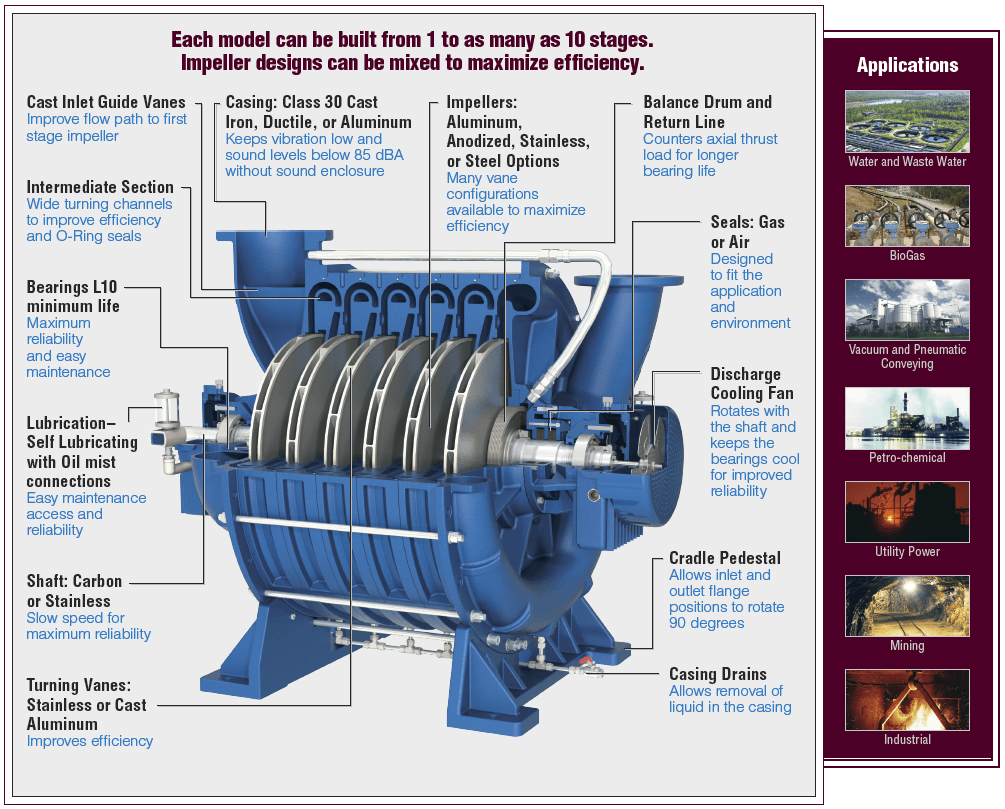

Each Model can be built from 1 to as many as 10 stages. Impeller designs can mixed to maximize efficiency

- • Designed for Variable Speed Applications

- • Larger Diameter Backward Curve Impellers

- • Higher Rise to Surge Allows more Flow Range with Speed Change

- • Most Existing Designed were based on Constant Speed

- • Reliable and Proven Technology

- • Very tolerant to adverse gas and particulates

- • Moisture is easily removed

- • Very slow RPM

- • Simple and Easy Maintenance

- • Under 85 dba without sound enclosure

- • Long Bearing Life

- • Direct coupled – no gears or belts

- • Oil Free Compression – No contamination

Impeller Types

Fabricated improve efficiency about 3% over cast impellers and have a higher strength to weight ratio.

Fabricated impellers can be made of aluminum, steel or stainless steel.

What We Call Standard, Others Call Options

- • O-Ring Sealing Between Cast Iron

- • No-Leak Design

- • Gas Tight Applications

- • Pressure to 35 psig

- • High Temperature Elastomer

- • High Velocity Cooling Fan for Discharge Bearing

- • Constant Level Oiler – Closed Loop for no leakage or misting

- • Deep Well Aluminum Oil Well –Optional cooler and heater can be connected.

- • Oil Splash Lubrication – Grease Option

- • Balance Drum and Return Line to Reduce Thrust and Increase Bearing Life

- • All Stainless fittings (standard)

Lone Star Offers Various Coatings for Hazardous Gas

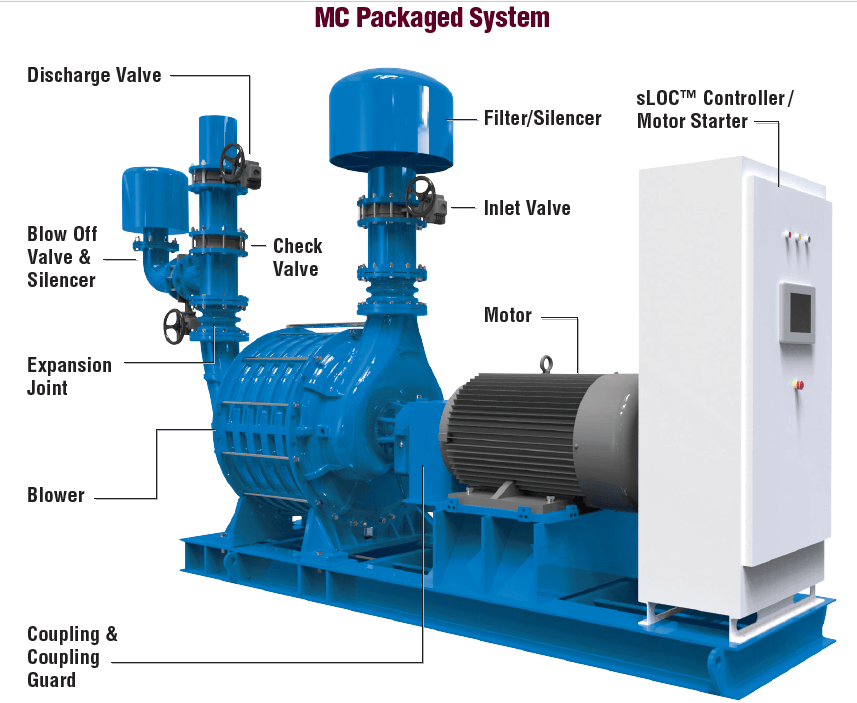

Packaged System Air Service

All accessories including motor, control panel, special designed inlet filter all pre engineered as a working system. Optional sound enclosure can be added for noise sensitive environments.

- • Complete Packages or Component Options

- • Standard or Custom Engineered

- • Tested as Complete Systems

- • Optional Hazardous Location to

- • Class1, Division 1

- • Zone 0

- • Atex